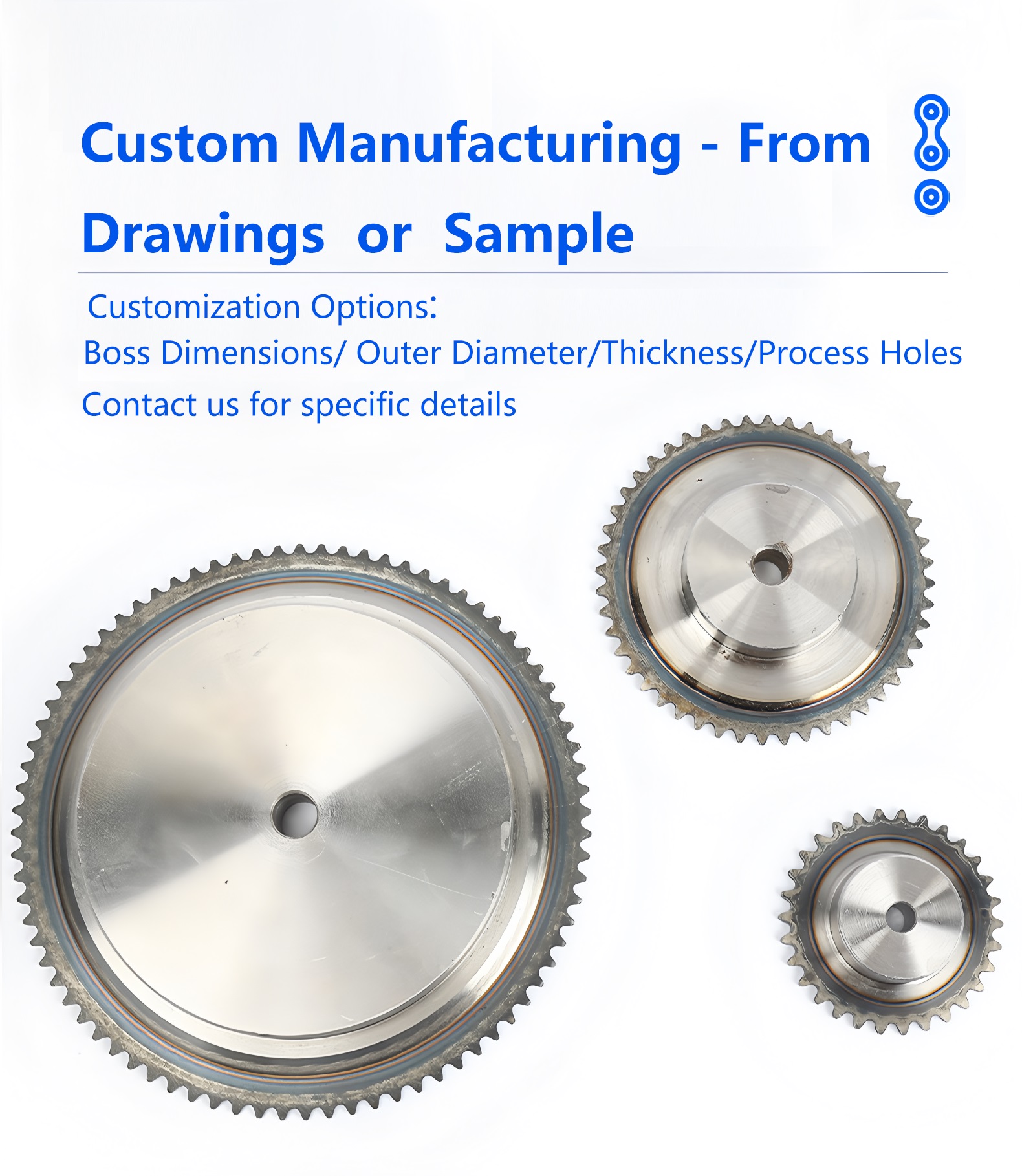

Custom Manufacturing Services

Custom Component & Structural Fabrication Solutions

- Processing Methods: Machining, bending, welding, or bolted assembly.

- Material Options: Carbon Steel, Aluminum Alloy, Alloy Steel, Stainless Steel, or custom materials as specified.

- Full Customization: All parts and structural components can be tailored to your drawings or samples.

- Fast Turnaround: 72-hour rapid prototyping available.

Manufacturing Advantages

- Small Batch Production: MOQ 50 pieces, free shipping for orders over 500 units

- Rapid Delivery: 48-hour feedback on 3D models/drawings + 7-day rapid prototyping

- Flexible Customization: OEM services for drawings or samples replication

- Factory Direct Pricing: 10%+ cost advantage vs. market equivalents at same quality

- Proven Reliability:

- 20,000+ hours failure-free operation

- Parent company supplies XCMG, SANY, NGC, etc.

- Engineering Expertise:

- Gear design services

- FEA analysis reports for gear meshing

- Precision Manufacturing:

- Class 7 precision gears

- Hardness HRC 60-62

- Specialized Solutions:

- Tropical Climate Components: Zn-Ni alloy plating (humidity resistance >90%)

- Lightweight Aluminum Pulleys: 10% energy reduction + easier facility upgrades

- Heavy-Duty Applications: German alloy steel (40% higher impact resistance)

- Food-Grade Pulleys: FDA-certified stainless steel for cleanroom conveyors

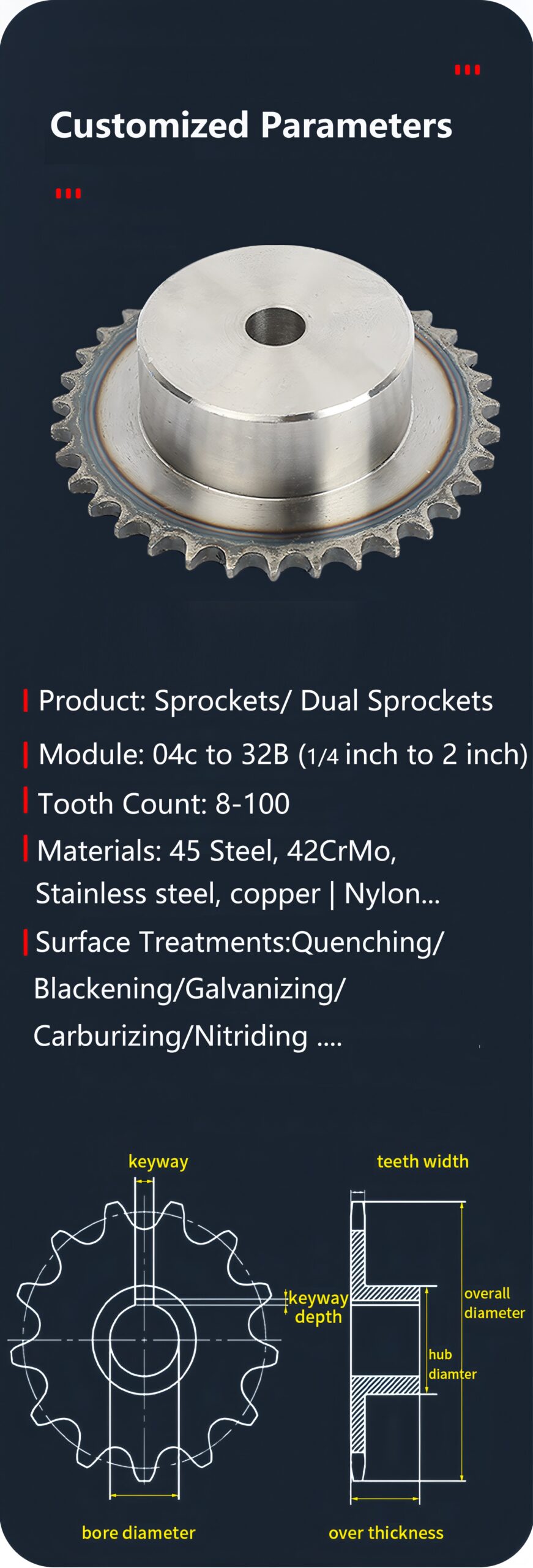

Technical Specifications

Iterm One

Iterm two

Iterm There

Iterm Four

Key Feature

Material Sourcing:

All steel materials are sourced from Ansteel Group (fully traceable)

Custom alloy materials available upon request (including German-imported alloys)

Production Capacity:

35 production lines in total:

21 gear shaping machines

12 gear hobbing machines

18 CNC machining centers

5,000㎡ large-scale workshop

30 skilled workers

Daily output: 700+ gears

Material traceability

23 large-scale ball mills, Ø5.5×8.8m

capable of mass production

6 wet grinding rod mills, Ø4.6×6.7m

CNC precision machining

1 SAG mill, Ø8.5×5.5m

CNC machines

6 SAG mills, Ø8.8×4.8m

5000 square meter factory

SAG mill, Ø9.75×4.88m

Full-process Solution for Mineral Grinding

We believe the projects that we have executed speak for themselves. CITIC HIC has engineered and provided 6 AG mills of Ø12.2m×11m (28000kW gearless drive) and 6 overflow discharge ball mills of Ø7.9×13.6m (2×9000kW gear drive) for Sino Iron Project in Australia. For Zijin Mining’s Duobaoshan Copper Mine project in Heilongjiang, we have manufactured and provided SAG mills of Ø11×6.4m (2×9000kW) and overflow discharge ball mills of Ø7.9×13.6m (2×9000kW) which have been well operating currently.

Why Choose CITIC HIC's Grinding Mills

- High cost-effectiveness

CITIC HIC grinding mills are recognized as China’s Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi-autogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cutting-edge design concept, and 60 years of experience in developing and nurturing innovative technology. - High operating rate

The long life cycle of our products is based on the adoption of international standards, high-quality materials, state-of-the-art processing techniques. - Low-carbon & environmental-friendly processes

Intelligent control technology coupled with long-life wear-resistant materials results in low-carbon and eco-friendly operations. - High-efficiency service

Our service network is distributed all over the world, and our service team of seasoned professionals is reliable and willing to assist along the way. We are able to deliver quick response to customer needs and provide full life cycle support via online monitoring and diagnosing, product upgrading and continuous process improvement.

Do you have any questions?

Other Products